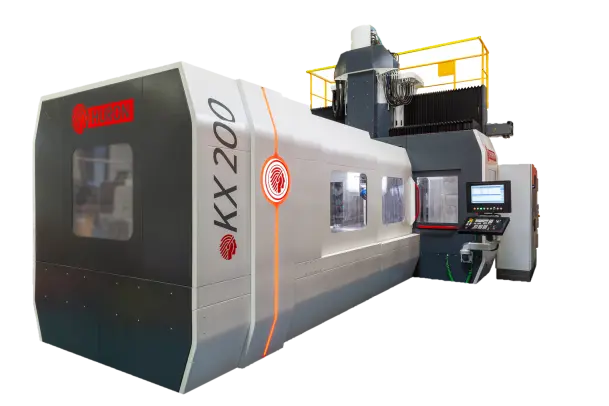

HURON KX Series: Precision in 5-Sided and 5-Axis Machining

The HURON KX Large Series is designed for superior performance in 5-sided and 5-axis machining of complex parts. Its fixed portal architecture ensures maximum rigidity, allowing for precise machining in various hard materials. Capable of handling workpieces up to 20 tons and machining volumes as large as 4,080 x 2,180 x 1,550 mm, this range is built for large-scale projects.

Engineered for high-performance roughing and finishing, the KX Series delivers exceptional accuracy in both positioning and 5-axis contouring. With a wide distance between columns, it maximizes the part volume, making it ideal for sectors like mold production, precision mechanics, aeronautics, and energy industries.

Key Features:

• High-performance spindle for both roughing and surfacing

• Excellent accuracy in complex part production

• Modular design with multiple configuration options to meet diverse customer needs

• Ideal for tooling, large part machining, and production of aeronautic and energy components

| X-Axis Travel | 3,300 mm | 129.92" |

| Y-Axis Travel | 2,300 mm | 90.551" |

| Z-Axis Travel | 1,000 mm | 39.37" |

| Table Size-X | 3,500 mm | 137.8" |

| Table Size-Y | 1,250 mm | 49.213" |

| Table Load Capacity | 12 T | 10,886.2 kg |

| Standard Spindle Taper | HSK63A | HSK63A |

| Optional Spindle Taper | HSK100A | HSK100A |

| Standard Spindle Speed | 15,000 RPM | 15,000 RPM |

| Optional Spindle Speed | 18,000 | 20,000 RPM | 18,000 | 20,000 RPM |

| Milling Head (2-axis) Type | Fork Head | Fork Head |

| A-axis Swivel | 105° | 105° |

| C-axis Rotation | 190° | 190° |

| ATC | 30 | 30 |

| Optional ATC | 60 | 120 | 60 | 120 |

| # Axis | 5 | 5 |

| CN Control | Heidenhain TNC640 | Heidenhain TNC640 |