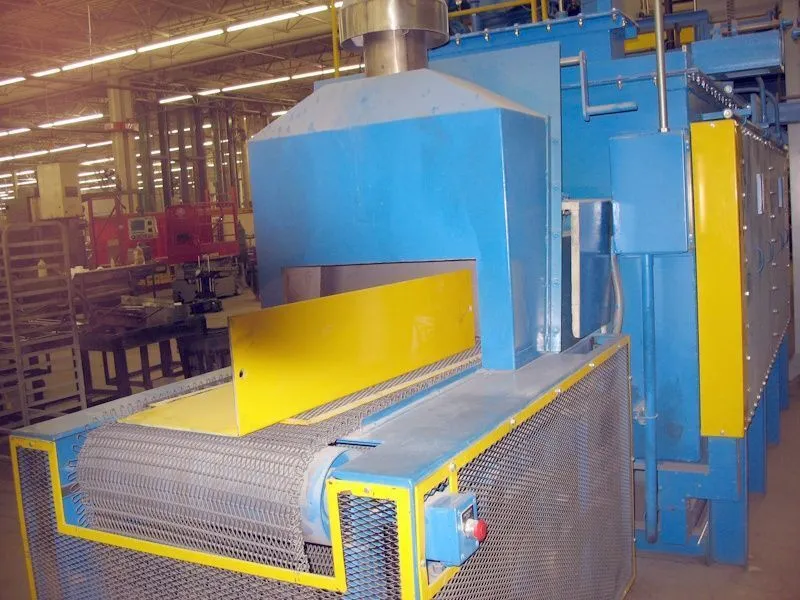

Manufacturer: JL Becker Company

Type: Electrically Heated Mesh Belt Brazing Furnace

Serial: J3454 (built 2007)

Max Temp: 2100ºF

Dimensions:

Load Table: 3’-0” long (from exit of flame curtain door to centerline of front idler roller)

Charge Vestibule: 3’-0” long

Preheat: 2’-8” long

Heating Chamber: 8’-0” long (effective heating area)

Pre Cool Section: 2’-0” long

Flange Plate Connection: 4” long

Cooling Sections: Three (3) 10’-0” long section

Atmosphere Curtain:

Discharge Hood 3’-6” long

Discharge Table 3’-0” long

Load Height: 41” high (from floor to belt)

Clear Height: above the belt: 11" high

Belt Width: 26" wide

Overall Dim’s: 7’-0” wide x 54’-1” long

Zones of control: Two (2)

Heat Input: 225 kW

Zone #1: 150 kW – 5 feet long

Zone #2: 75 kW – 3 feet long

Operating Temp: 2050°F

Maximum Temp: 2100°F

Belt speed: Variable

Design speed: 9.6"/min

Estimated Capacity: 964 lbs./hr.

Belt Loading: 18 lbs./lineal foot

Controls:

Honeywell UDC 2500 Hi Limit controller

Type K thermocouples

Variable belt speed Fuji AC drive controller

Temperature control: JL Becker Computer Management System (CMS)

Allen Bradley SLC PLC,

Color monitor with terminal for operator input.

Furnace Case: Mild steel, welded gas tight; adjustable internal doors at charge and discharge ends; doors manually operated by handle through RC-40 sprockets and roller chain.

Insulation:

Sidewalls: 4½” of 2600ºF insulating firebrick (IFB),

4½” of 2000ºF (IFB)

4½” of high temperature block

Floor: 11" of insulating brick facing heated area

Roof: 12" ceramic fiber stud welded to roof plate

Floor: Supports refractory piers which support hearth plates; belt supported through furnace on silicon carbide hearth plates

Heat Input: 225 kW

Zone #1: Twenty-four (24) Silicon Carbide heating elements – 150 kW, complete with SCR power controller and Marelco Scott-T type multi tap changing transformer, (6) secondary taps

Zone #2: Twelve (12) Silicon Carbide heating elements - 75 kW, complete with SCR power controller and Marelco Scott-T type multi tap changing transformer, (6) secondary taps