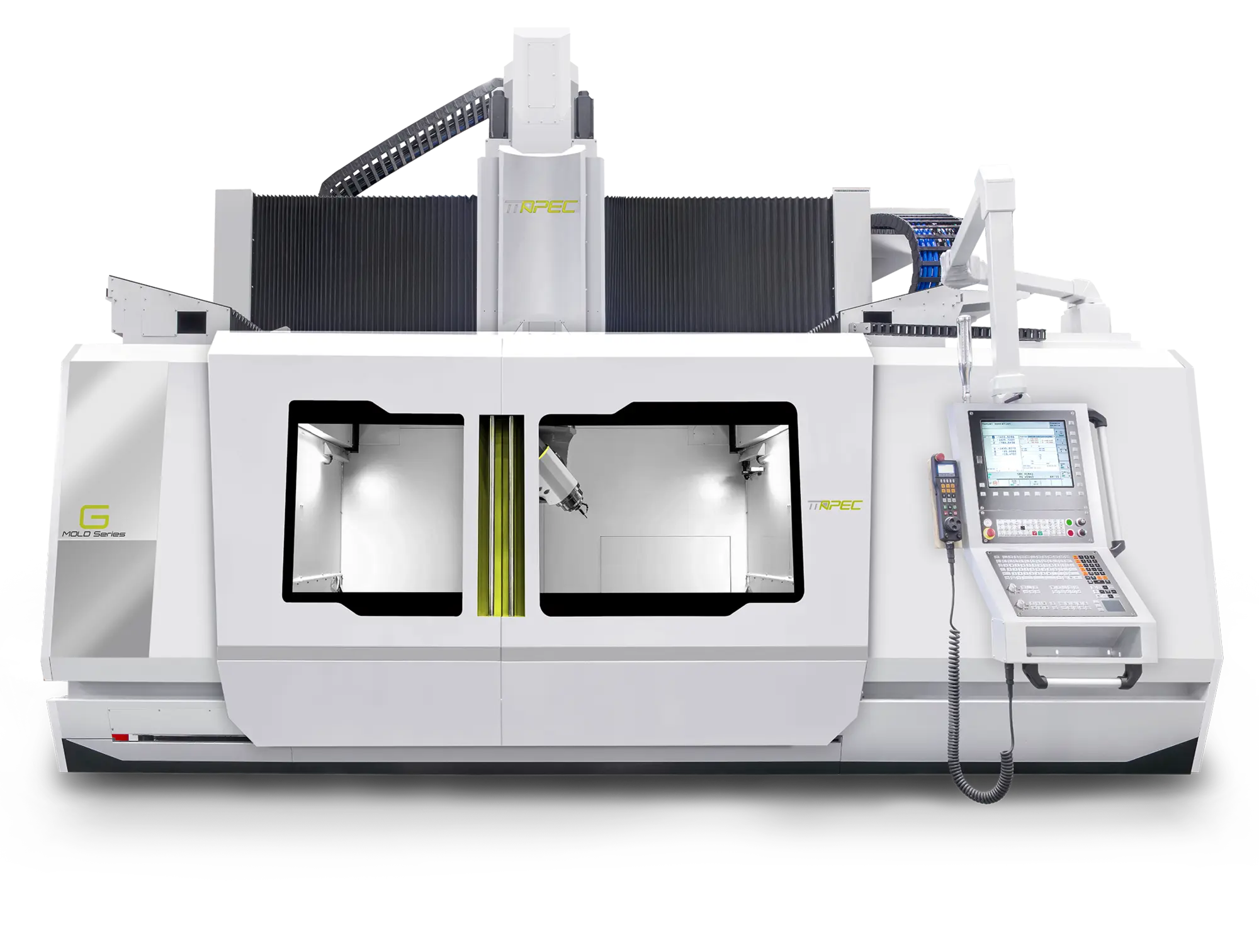

Experience unmatched precision and efficiency with the APEC G3020 5-Axis Gantry Vertical Milling Center — a next-generation solution for complex and high-performance machining. Engineered for aerospace, automotive, and mold-making industries, the G3020 delivers superior accuracy, dynamic performance, and thermal stability, handling diverse materials and intricate geometries with ease.

Built on a rigid U-shaped structure, the APEC G3020 combines linear motor-driven X/Y axes and a hollow water-cooled Z-axis to ensure exceptional positioning accuracy and maximum stability even during heavy-duty cutting operations. Its compact two-axis milling head delivers high torque and smooth contouring, making it ideal for aerospace machining, automotive components, precision mold & die making and complex 5-axis parts.

Key Features:

• Large Travel Range: 3,000 mm (X) × 2,000 mm (Y) × 1,200 mm (Z) — ideal for machining large workpieces.

• Precision 2-Axis Milling Head: ±115° (B-axis) and ±360° (C-axis) swivel rotation, with 4,000 Nm clamping torque.

• Thermal Stability: Water-cooled Z-axis and cooler-equipped linear motors for consistent precision machining.

• Accuracy: Positioning precision of up to ±0.010 mm and repeatability of ±0.008 mm per VDI/ DGQ 3441 standard.

• Integrated workpiece touch probe and tool measurement system for automatic calibration.

• Efficient Chip Management: Standard chip conveyor and water tank for cleaner operation.

• Enhanced Reliability: Germany braking system for linear motors, counterbalance system, and air-conditioning for electrical cabinet.

Why Choose the APEC G Series?

Combining high-speed cutting, robust construction, and intelligent thermal management, the APEC G3020 helps you elevate your 5-axis CNC machining capabilities. Whether it's aluminum aerospace structures, complex automotive parts, or heavy-duty molds, this machine guarantees precision, versatility, and productivity.

| X-Axis Travel | 2,000 mm | 78.74" |

| Y-Axis Travel | 3,000 mm | 118.11" |

| Z-Axis Travel | 1,000 mm | 39.37" |

| Spindle End to Table Distance | 260-1460 mm | 260-1460 mm |

| Table Size-X | 2,000 mm | 78.74" |

| Table Size-Y | 3,000 mm | 118.11" |

| Spindle Speed | 15,000 RPM | 15,000 RPM |

| Spindle Taper | HSK63A | HSK63A |

| Spindle power (S1/Max) | 45/54 kW | 45/54 kW |

| Spindle torque (S1/Max) | 119/143 Nm | 119/143 Nm |

| Swivel/Rotation Speed | B/C 60RPM | B/C 60RPM |

| Swivel/Rotation Torque | B/C 1,980/1 740 Nm | B/C 1,980/1 740 Nm |

| Clamping Torque | B/C 4,000 Nm | B/C 4,000 Nm |

| ATC | 30 | 30 |

| Max. Tool Length | 450 mm | 17.717" |

| Max. Tool Weight | 15 kg | 33.1 lb |

| CN Control | Heidenhain TNC640 | Heidenhain TNC640 |

HEIDENHAIN TNC640 WITH HR520 MPG

AGA FORK TYPE 2-AXIS MILLING HEAD

EXTENDED Z-AXIS TRAVEL TO 1,200 MM

15,000 RPM BUILT-IN SPINDLE

UPGRADE TAPER TO HSK100A

60 TOOLS ATC MAGAZINE

X/Y-AXIS WITH LINEAR MOTOR DRIVE / Z-AXIS WITH BALL-SCREW DRIVE

X/Y/Z-AXIS WITH HIGH RIGIDITY ROLLER TYPE LINEAR GUIDE-WAY

70 BAR COOLANT THROUGH SPINDLE SYSTEM AND AIR THROUGH THE SPINDLE

AUTOMATIC KINEMATICS MEASUREMENT & CALIBRATION SYSTEM WITH CERAMIC BALL SET

BLUM WORKPIECE TOUCH PROBE

BLUM TOOL MEASURING SYSTEM

COOLER FOR LINEAR MOTORS

GERMANY BRAKING SYSTEM FOR LINEAR MOTOR

5 AXES WITH HEIDENHAIN OPTICAL LINEAR/ CIRCULAR SCALE

AIR-CONDITIONER FOR ELECTRICAL CABINET

SPINDLE CHILLER

OIL-AIR LUBRICATION DEVICE FOR SPINDLE

COOLANT AROUND SPINDLE

OIL MIST AROUND SPINDLE

STANDARD CHIP CONVEYOR SYSTEM

STANDARD WATER TANK

SECURITY DOOR INTERLOCKS

COUNTER BALANCE SYSTEM

WATER-PROOF WORKING LAMP

AIR DRYER

AUTOMATIC OPEN/CLOSE TOP ROOF SLIDING COVER