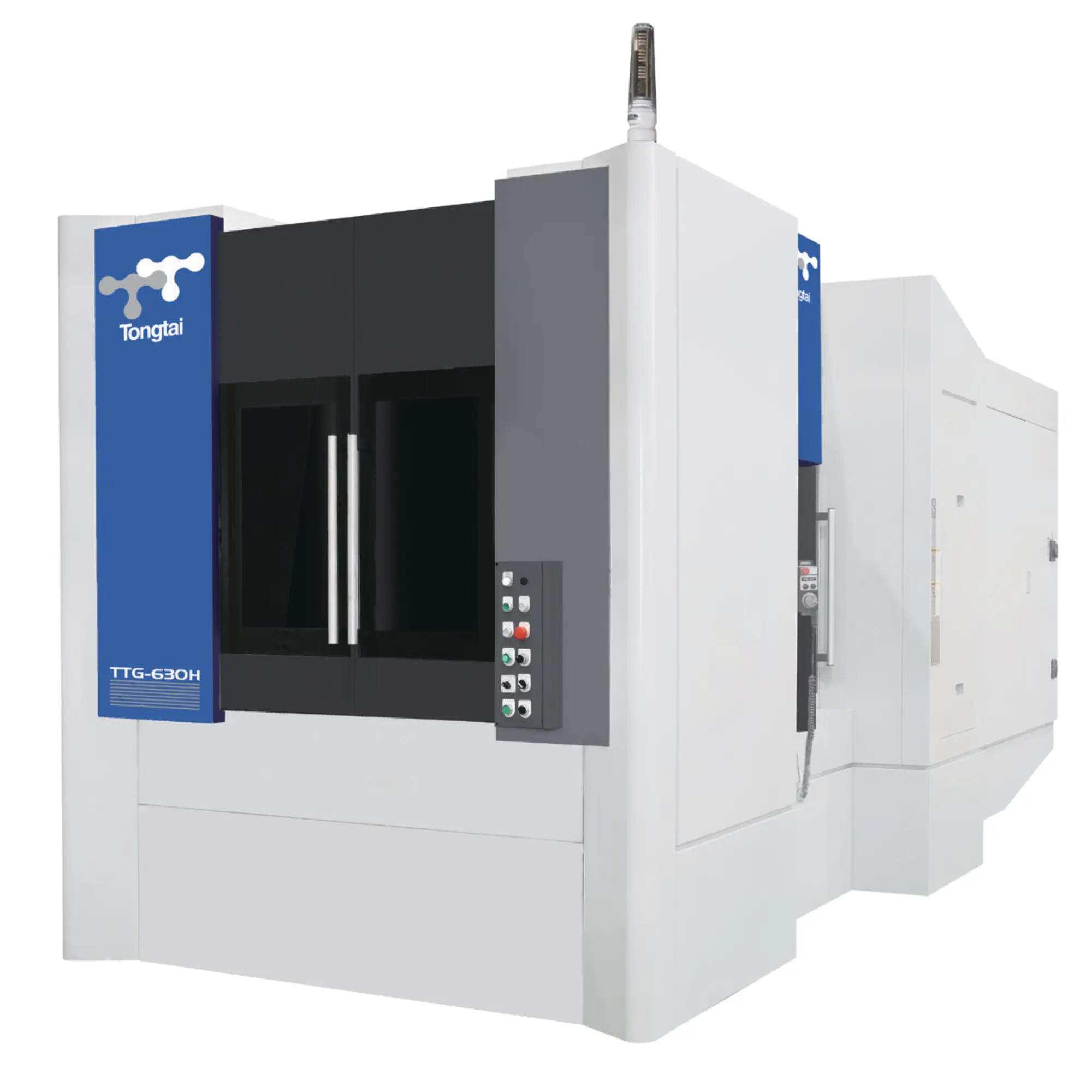

The TONGTAI TTG-630H Horizontal Machining Center is a robust 4-axis solution engineered for heavy-duty, high-precision applications across industries such as aerospace, automotive, mold and die, and general machining. Designed with a traveling column and box-type structural frame, this machine offers exceptional rigidity for stable machining under high loads. It features a 630 mm x 630 mm rotary pallet system with a maximum load capacity of 1,200 kg per table, making it ideal for large workpieces such as engine blocks, structural aerospace components, hydraulic housings, and mold bases.

The machine is equipped with a 60-tool automatic tool changer (expandable to 90 or 120), dual-pallet changer for reduced idle time, and FANUC 0i-MF Plus CNC control with support for advanced tool path strategies and integration with automation systems. Optional features such as through-spindle coolant and chip conveyor systems further enhance its performance for long-cycle, high-volume production environments. Whether you're machining aerospace brackets, transmission housings, mold plates, or industrial fixtures, the TTG-630H delivers the power, precision, and flexibility required for complex and high-value machining tasks.

Key Features:

• X / Y / Z travel range over 1,000 mm for larger parts

• Built-in or gear-driven spindle options, up to 18,000 RPM

• 4-axis capability with 0.001° B-axis indexing

• Dual-pallet changer for continuous machining

• Expandable tool magazine (60, 90, or 120 tools)

• FANUC 0i-MF CNC control system

• Through-spindle coolant and effective chip evacuation system

| X-Axis Travel | 800 mm | 31.496" |

| Y-Axis Travel | 800 mm | 31.496" |

| Z-Axis Travel | 830 mm | 32.677" |

| Max Workpiece | Ø900 x 1000 MM | Ø900 x 1000 MM |

| Table Size - X | 500 mm | 19.685" |

| Table Size - Y | 630 mm | 24.803" |

| Table Capacity | 1,000 kg | 2,204.6 lb |

| Table Height From Floor | 1,220 mm | 48.032" |

| Spindle Center to Table | 880 mm | 34.646" |

| Spindle Nose to Table Center | 900 mm | 35.433" |

| X/Y/Z Axis Rapid | 80 M/MIN | 80 M/MIN |

| Spindle Speed | 15,000 RPM | 15,000 RPM |

| Spindle Taper | CAT40 | CAT40 |

| Tool Magazine Capacity | 60 | 60 |

| Max Tool Dia | 170 mm | 6.6929" |

| Tool Length | 410 mm | 16.142" |

| Tool Weight | 10 kg | 22 lb |

| Rotations Diameter | 900 mm | 35.433" |

| Parts Length/Clamping | 1,000 mm | 39.37" |

| Numeric Control | FANUC 0i-MF PLUS | FANUC 0i-MF PLUS |

FANUC 0i-MF PLUS WITH 15" LCD SCREEN

AICCII (400 BLOCKS) + 2GB DATA SERVER

SPINDLE MOTOR 30/26/18.5 KW (S3-10 MIN./S2-15 MIN./S1-CONT.)

15000 RPM BUILT-IN SPINDLE, CAT40 BIG PLUS

60 TOOLS ATC MAGAZINE

SPINDLE COOLER

COOLANT THROUGH SPINDLE SYSTEM WITH POLARJET HIGH PRESSURE PUMP & FILTER (1000 psi)

2 PCS x APC WITH WORKING TABLE

MACHINE INTERNAL COOLANT FLUSHING

DUAL USE ROTARY JOINT (AIR/COOLANT)

ADDITIONAL PUMP FOR INTERNAL COOLANT SHOWERS

ROTARY ENCODER FOR B AXIS

OIL SKIMMER (DISC TYPE)

CHIP CONVEYOR (SCRAPER TYPE) H=1100 MM WITH TROLLEY

MACHINE ROOF OVERHEAD COOLANT FLUSHING

CENTRAL LUBRICATION FOR X/Y/Z AXIS

TELESCOPIC COVERS FOR X/Y/Z AXIS

STANDARD FULL SPLASH GUARD

ELECTRICAL CABINET WITH HEAT EXCHANGER

MANUAL PULSE GENERATOR

FOUR COLOR WARNING LAMP (R/Y/G/B)

WORK LIGHT (LED)

DOOR INTERLOCK

RIGID TAPPING

COOLANT GUN

AIR GUN

M CODE 8 SETS

AUTO POWER OFF