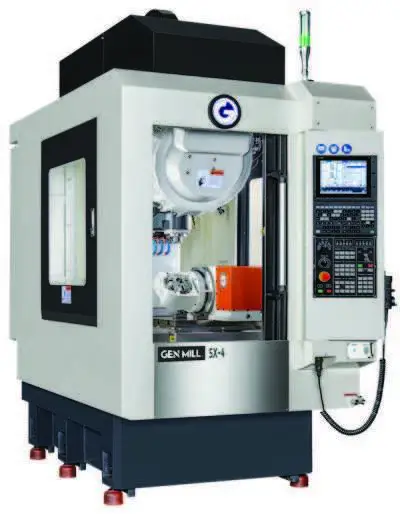

510MM HIGH SPEED MILL-DRILL-TAP CENTER

4-Inch Zero-Backlash Roller Gear Cam Tilting Rotary Table

12,000 RPM Inline Direct-Drive Beltless Spindle

7.5-HP spindle motor with 6000 RPM Synchronous Rigid Tapping

BT #30 BBT Dual Contact “Big-Plus” Spindle

21-Tool Drum Turret with 1.6-Second Tool-to-Tool tool change time2,362 IPM rapid rates in X, Y & Z axis for fast production

AXIS TRAVEL

X-Travel

20.08” 510mm

Y-Travel

16.93” 430mm

Z-Travel

12.99” 330mm

Spindle Nose to Rotary Table Surface

9.05” – 22”, 230 – 560mm

Spindle Center to Column

18.50” 470mm

SPINDLE

Spindle Motor – Mitsubishi DJ-D5.5/120-01 7.5-HP

3.7/5.5kw 25% Duty-Cycle

Spindle Motor Coupling

Inline Direct-Drive, Beltless Spindle Drive

Spindle Speed

12,000 rpm 15,000 RPM optional

Synchronous Tapping Speed Limit

6,000 rpm

Tapping Performance in Production

M20x2.5 in aluminum, M14x2.0 in steel

Drilling Performance in Production

38mm in aluminum, 25mm in steel

Spindle Torque

26 ft-lb force, 35Nm up to 1,500 RPM, 17.7Nm continous

Tool Type

BT #30, 4-bearing spindle – 2-top, 2-bottom

Spindle Bearing – Inner Diameter

40mm, P4 class-7, steel ball bearings

Spindle Material / Hardness

SCM415 / HRC 58-62

Spindle Runout

≤ 0.000040” T.I.R., Pull Stud USST B30-4500H

Retention System / Holding Capacity

MAS-P30T-1, Bellville Spring Stack / 1650-1760 lbs.

AXIS FEEDS

Rapid Traverse – X/Y/Z

2,362 ipm 60/60/60m / minute

Rated Cutting Feedrate – X/Y/Z

0.04 – 1181 ipm 30/30/30m/minute

Mechanical Way System – X/Y/Z

Roller-Bearing Ways, Roller-Ways -30/30/35mm width

Axis Drive Motor Power – X, Y/Z

2.0-HP / 3.0-HP 1.5kw / 2.2kw with brake

Axis Thrust Force – X, Y/Z

3335 lbs. / 3692 lbs. 14840 N / 16430 N

Ballscrews – X, Y, Z

32mm Ballscrews, 16mm Pitch

Positioning Accuracy – X/Y/Z

±0.00015” ±0.004mm

Positioning Repeatability – X/Y/Z

±0.00008” ±0.002mm

Least Input Command Increment

0.0001” / 0.000040” 0.001mm / (40-millionths in metric)

TOOL CHANGER

Tool Capacity

21-Tools, Drum Turret

Tool Shank

BT#30, MAS P30T-1 Pull-Stud

Tool Change Time

1.6-sec. tool-to-tool, Servo motor driven

Maximum Tool Diameter / with adjacent tool

2.36” / 3.15” 60mm / 80mm with no adjacent tool

Maximum Tool Length / Weight

7.87” / 6.6 lbs. 200mm / 3 kg

Tool Selection / Tool Access

Random access Bi-directional shortest path

SPECIFICATIONS

Air Service Requirements

85 psi @ 5-scfm 6 Kg/cm2

Connected Load Electrical Requirements

16kva, 40 Amps 220vac ±5%, 3-Phase, 60-Hz

Coolant Tank Capacity

32-gallons / 120 liters

Coolant Pump (Cutting Tools) – HP / Pressure

1.0-HP / 45 PSI, .75kw Grundfos MTH4-30/3A

Coolant Pump (Chip Flush Pump)

1.0-HP .75kw

Floor space requirements (W x D x H)

49.2” x 105” x 109” 125x267x276cm (+ chip conveyor)

Machine Weight

6,408 pounds 2,910 kg

Warranty – 1-year machine warranty

3-year Mitsubishi control, motors, & drive warranty